General information

DSR mainly characterizes the viscous and elastic behavior of bituminous samples and mortars by measuring the complex shear modulus and phase angle. The basic working principles are based on the European norm EN 14770 according to which an oscillatory shear stress or strain is applied in controlled temperature and test geometry. The response to this stress is translated to strain or stress respectively. Different materials can be tested in a DSR for determination of viscosity or rheological properties:

- Bitumen

- Mastics

- Mortars

- Polymers

- Gels

- Creams

- Oils

- Liquids

Different testing geometries and types of tests can be performed with a DSR. It is considered vital for asphalt industry to evaluate the performance of newly assessed modifiers, rejuvenators as well as the healing and ageing influence for the bituminous binders, mastics and mortars. Thus, a number of tests can be performed in our labs, in one of the three DSRs.

Standardized tests

- NBN EN 14770 - Determination of complex shear modulus and phase angle - Dynamic Shear Rheometer (DSR)

- NBN EN 14023 - Specification framework for polymer modified bitumen

- NBN EN 13302 - Determination of dynamic viscosity of bituminous binder using a rotating spindle apparatus

Non-standardized tests

- Fatigue and frequency sweep test for mortar samples using steel rings [1]

- Low-temperature testing of bituminous samples using 4 mm plate geometry [2]

- Linear amplitude sweep (LAS) test [3]

- Time sweep tests for viscosity and modulus evolution (useful for thermosets) [4]

A sophisticated rheological software package (RHEATM, Abatech Engineering Consultants) is used for the determination of advanced rheological properties and the construction of master curves.

- Glover-Rowe parameter [5,6,8]

- Crossover modulus and temperature [6]

- Shape parameter R [7]

- Difference of critical temperatures ΔΤc [7,8]

Types of DSRs

Our labs possess three different types of DSRs, each of them dedicated to a specific series of test.

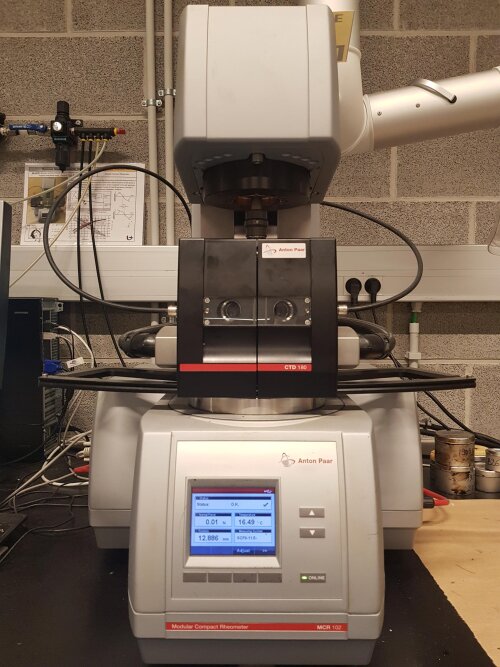

Anton Paar MCR 102

It is equipped with temperature controller (-10 to 200°C) and special accessory for clamping rings for mortar samples. The maximum applied torque can reach up to 200 mNm.

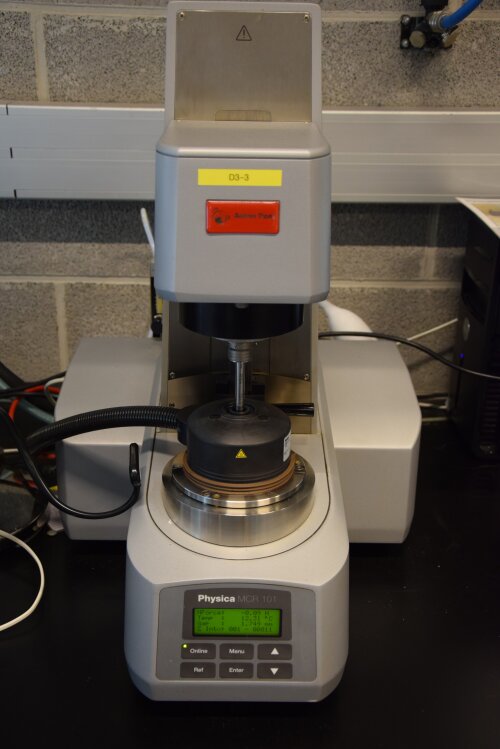

Anton Paar Physica MCR 101

This DSR is used for the determination of viscosity using cone plate geometries as well as for low temperature testing with a 4 mm geometry.

Anton Paar Physica MCR 500

This device performs routine as well as fatigue and relaxation rheology tests in a range of temperatures (-20 to 200°C) using 8 and 25 mm plate geometry.