Nanostructured metals and alloys

The recent evolution in materials sciences towards the nanoscale also influenced research in metals and alloys. Not only the observation that “smaller is stronger” but also the strong effects on other properties drives the research. Systems currently under study at EMAT are metallic nanobeams investigated before and after deformation revealing important contributions of coherent Σ3 {111} nanotwins to the enhanced ductility and hardness.

The work has revealed possible formation mechanisms for these nanotwins, their interaction with dislocations, their relation to incoherent Σ3 {112} nanotwins, etc. After hydriding Pd beams an unexpected 9R structure was observed.

Phase transformations in alloys are an important aspect of many functional materials that exhibit extensive responses to external inputs. A typical example are martensitic transformations that induce shape memory and superelastic behaviour under changing temperature, stress or even magnetic field. Such materials have found applications in a variety of fields including micromechanics, actuators, dentistry, surgery, etc. The underlying structural aspects, which often lead to large quasi-periodic micro- and nanostructures and which can be influenced by precipitates or lattice defects, are investigated by a variety of EM techniques, including quantitative HRTEM, EELS, in-situ TEM, electron tomography and FIB/SEM slice-and-view.

Most recent work at EMAT has been concentrated on Ni-Al- and Ni-Ti-based alloys including ternary systems and prepared as bulk, melt-spun, splat-cooled, thin film or nanostructured materials. Results are interpreted in view of theoretical concepts, e.g., dealing with symmetry breaking transformations or in view of thermomechanical applications.

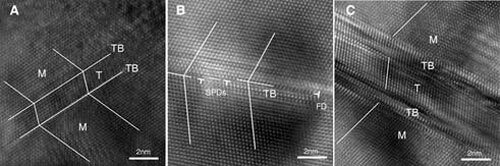

FIGURE LEGEND

(a) undeformed Pd beam with coherent growth nanotwins, (b) a beam deformed at 0.8% showing a twin with interacting dislocations, (c) a completely incoherent twin after 4% strain

(DOI: 10.1002/adma.201004160)

The movie shows the arrangement of Ni4Ti3 precipitates in a Ni-Ti single crystal annealed for 10 hours at 550 °C and obtained by FIB/SEM slice-and-view. The precipitates grow in autocatalytic pockets of single variants (different colours in the movie)

(DOI: 10.1016/j.scriptamat.2012.01.045)