What is a gas discharge and what is it used for ?

A gas discharge is a kind of plasma. It is an ionised gas consisting of equal concentrations of positive and negative charges and a large number of neutral species.

In the simplest case, it is formed by applying a potential difference (of a few 100 V to a few kV) between two electrodes that are inserted in a cell or reactor (or that form the reactor walls). The reactor is filled with a gas (an inert gas or a reactive gas) at a pressure ranging from a few mTorr to atmospheric pressure.

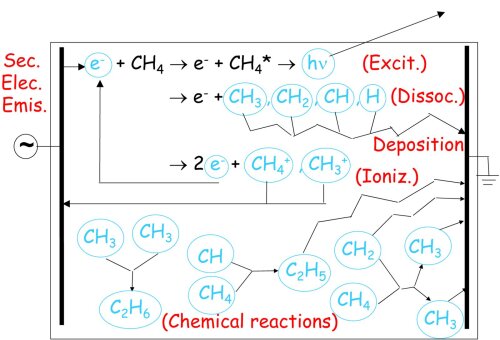

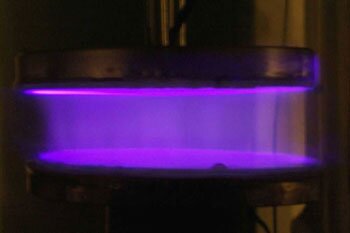

Due to the potential difference, electrons that are emitted from the cathode by the omnipresent cosmic radiation, are accelerated away from the cathode, and give rise to collisions with the gas atoms or molecules (excitation, ionisation, dissociation, …). The excitation collisions give rise to excited species, which can decay to lower levels by the emission of light. This process makes that a gas discharge plasma typically emits a characteristic glow (and is therefore also called “glow” discharge). The ionisation collisions create ion-electron pairs. The ions are accelerated toward the cathode, where they release secondary electrons. These electrons are accelerated away from the cathode and can give rise to more ionisation collisions. In its simplest way, the combination of secondary electron emission at the cathode and ionisation in the gas, gives rise to a self‑sustained plasma.

The dissociation collisions (in the case of a molecular gas) yield the formation of radicals, which are very reactive. They can chemically react with the walls of the reactor, resulting in coating formation (by deposition) or surface modification, for materials science applications, or trench formation (by etching or sputtering) for microelectronics applications. Alternatively, they can chemically react with other species in the plasma, resulting in new molecules (plasma chemistry). This makes the plasma a kind of chemical reactor, where reactions can occur at ambient conditions, which would thermodynamically require high temperature.

These processes are schematically illustrated in the figure below.

As explained above, due to the various collision processes in the plasma, a large number of different plasma species can be present: electrons, atoms, molecules, several kinds of radicals, several kinds of (positive and negative) ions, excited species, etc. These different species can all be in interaction with each other, making the gas discharge plasma a complicated gas mixture. The aim of our work is to obtain a better insight in the complex processes occurring in gas discharge plasmas and related plasmas, and we try to do that by numerical simulations.

We have developed Monte Carlo models, particle-in-cell Monte Carlo simulations, fluid models, collisional-radiative models and hybrid codes. Currently we are mainly using 0D chemical kinetics models and 2D or 3D fluid models. We have investigated various kinds of plasmas, such as direct current (dc), radio-frequency (rf), pulsed and magnetron discharges, and more recently (packed bed) dielectric barrier discharges, microwave plasmas and gliding arc discharges, in different kinds of gases (argon, helium, nitrogen, methane, silane, CF4, air, CO2, as well as various gas mixtures). We describe the behaviour of different kinds of plasma-species (e.g., electrons, ions, radicals, atoms, molecules and excited species).

Different variants to gas discharge plasmas

The gas discharge (or glow discharge) described above can be called the “basic version”. In this direct current (dc) glow discharge, a continuous potential difference is applied between cathode and anode, giving rise to a constant current. However, this set-up gives problems when one of the electrodes is non-conducting, as is the case in some applications (see below). Indeed, due to the constant current, the electrodes will be charged up, leading to burn-out of the glow discharge.

This problem is overcome by applying an alternating voltage between the two electrodes, as in the capacitively coupled radio-frequency (cc rf) glow discharge. Indeed, the charge accumulated during one half of the cycle, will be neutralized by the opposite charge accumulated during the next half-cycle.

Beside a time-dependent rf voltage, an alternating voltage can also be applied in a lower frequency range, giving rise to an alternating current (ac) glow discharge. This can be considered as a consecution of short discharges, in which the two electrodes alternatingly play the role of cathode and anode. An important type of ac glow discharge, operating at atmospheric pressure, is the dielectric barrier discharge (DBD), where the electrodes are typically covered by a dielectric barrier.

A variation to the ac discharge is the pulsed glow discharge, which also consists of short glow discharges (with lengths typically in the milli- or microsecond range), followed by an afterglow, which is generally characterized by a longer time-period. The advantage is that high peak electrical powers can be reached for a low average power, resulting in high peak efficiencies for various applications.

In addition to applying an electric field (or potential difference), a magnetic field can also be applied to a glow discharge. The most well-known discharge type with crossed magnetic and electric fields is the magnetron discharge. The electrons circulate in helices around the magnetic field lines and give rise to more ionisation. Hence, magnetron discharges are typically operated at lower pressures and higher currents than conventional glow discharges.

There exist also other discharge types characterized by low pressure and high plasma densities, which have their main application in the semiconductor industry and for materials technology. The major difference with the conventional glow discharge is that the electrical power is not applied through a potential difference between two electrodes, but through a dielectric window. The two most important “high-density sources”, are the inductively coupled discharge, where the rf power is inductively coupled to the plasma, and the electron cyclotron resonance reactor, where microwave power and a magnetic field are applied.

Microwave power can also be applied in so-called microwave induced plasmas. Various discharge types can be classified under this name, among others the resonance cavity plasmas, free expanding plasma torches and surface wave discharges.

In fact, the list of gas discharge plasmas is longer than this. But because they are at this moment beyond the research interest of our group, we will not go into detail here. More information can be found in: A. Bogaerts, E. Neyts, R. Gijbels and J.J.A.M. van der Mullen, Gas discharge plasmas and their applications, Spectrochimica Acta B, 57, 609-658 (2002).

Applications of gas discharges

Gas discharges and related plasmas are used in a large number of application fields. They are applied in the microelectronics industry and in materials technology, for surface treatment, etching of surfaces (e.g., for the fabrication of integrated circuits), deposition of thin protective coatings, plasma polymerisation, plasma modification of polymers and other surfaces.

The excitation and light emitting character of discharge plasmas is also used for several interesting applications, such as in the light industry (e.g., fluorescence lamps, neon advertisements), as gas lasers, and as flat plasma display panels for the flat, large area television screens.

Furthermore, they are used in analytical chemistry, for the spectrochemical analysis of solids, liquids and gases, by combination with mass spectrometry or optical emission spectrometry. Because a lot of chemical reactions take place in the plasma, several types of discharges (mainly atmospheric pressure glow discharges, dielectric barrier discharges and corona discharges) find also increasing interest for environmental applications, e.g., for the destruction of volatile organic compounds, or for the conversion of greenhouse gases into value-added chemicals. This application field is of special interest for us, where we also investigate the effect of a catalyst in the discharge (i.e., plasma catalysis).

Last but not least, atmospheric pressure plasmas are gaining increasing interest for medical applications, i.e., plasma medicine, e.g., for the sterilisation of materials (bacteria killing), but also for the treatment of skin diseases, dental cavities, delicate surgeries, and cancer treatment. We are studying the latter application by experiments and computer simulations.