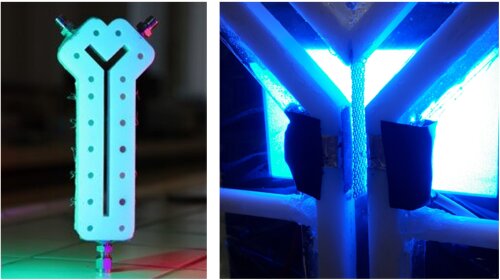

Membraneless electrolyzers for green H2 production

Electrolyzers are used to produce green H2 from water using renewable electricity. They rely on membranes to keep the H2 gas pure, which comes at a cost. Our Ydrogen technology enables to retain over 99% gas purity, without membranes, paving the way towards robust and affordable green H2 production.

Situation before

Commercially available electrolyzers for green H2 production rely on the use of membranes or diaphragms that separate the device in a cathodic compartment for H2 evolution, and an anodic compartment for O2 production. These polymeric membranes or diaphragms do not only significantly contribute to the overall installation cost, but they are also fragile and subject to fouling, resulting in frequent system failure by even minute impurities in the feed water, which again comes at a cost. Our membraneless electrolyzer offers an alternative technology to tackle these challenges by simply getting rid of the membrane or diaphragm altogether, while retaining over 99% of gas purity.

Technology

Ydrogen is a membraneless electrolyzer technology. By losing the membrane or diaphragm, all of its associated problems are also eliminated. In our technology, the flow of the electrolyte serves as a dynamic wall that keeps the gasses separated. Membraneless operation ensures that the technology is fundamentally robust and versatile. Firstly, it can withstand impure water with a total dissolved solids (TDS) content over several thousands. Secondly, the same cell configuration can operate with both acidic and alkaline electrolytes. Thirdly, it can operate seamlessly with variable load during intermittent renewable energy generation. Due to the absence of the membrane, the capital cost of the system can be reduced by 40% compared to commercial electrolyzers, and to that one can add lower downtime and water pretreatment costs.

Video: Membraneless electrolyzers for green H2 production

Partners we search for

We are looking for partners or licensees to commercialize this membraneless technology. Potential partners can be engineering firms with expertise in electrolyzers for building a scaled-up prototype. The technology is also relevant to business cases for on-demand local production and use of H2

About the researchers

Ydrogen is a technology entirely developed within the Verbruggen Lab at the department of Bioscience Engineering of UAntwerp (Verbruggenlab.com). The Ydrogen project is coled by FWO postdoctoral researcher Dr. Rituraj Borah. The group of Prof. Sammy Verbruggen broadly focuses on photo-electro-catalysis for sustainable energy and environmental applications, from fundamental materials science to innovative reactor system development.

IP position

A patent application is published under number WO2023232988.

More information

University of Antwerp

Valorisation Office

Middelheimlaan 1

2020 Antwerp - Belgium